Aluminum profiles for windows doors! |

Home >> Aluminium profiles |

aluminum profiles are mostly made with anodizing or powder coating. Anodizing colors include anodized silver, anodized champagne, anodized bronze, anodized black; Powder coating colors are not limited such as white, black, bronze, grey etc; Some two acid polished aluminum profiles have color of golden, violet gold. Before anodizing, pre-treatment methods like sand blasting get matt surface, polishing get bright and shining surface, brushing get satin surface; After coating, wood grain aluminum profile is achieved by wrapped with thermal transfer printing paper then curing in a vacuum wood grain machine. Electrophoretic painting can be the last process to cover acrylic resin paint evenly on the aluminium profiles and sealed without porosity. |

|

|

| |

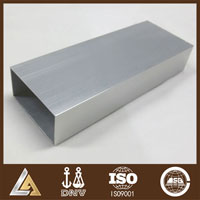

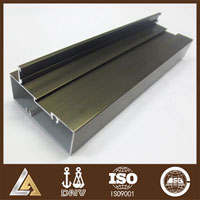

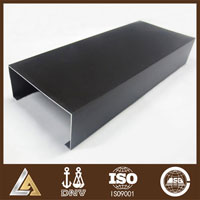

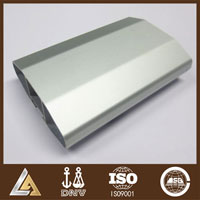

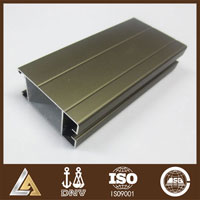

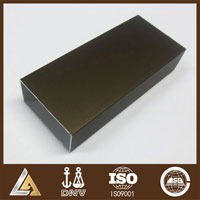

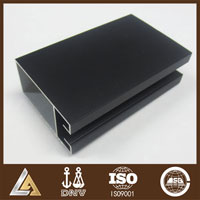

Anodized aluminum profile

Anodising is an electrochemical process to preserve the finish of aluminium and enhance corrosion resistance by formed a natural oxide layer on the profile surface. Profiles are pre-treated, anodised, colored and sealed as a complete anodising process. It create a decorative and dirt-repellent surface with durable color and gloss, and gives surface an electrically insulating coating, usually 8-10μm oxide layer thickness for indoors. |

|

|

|

|

| anodized silver |

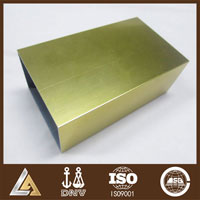

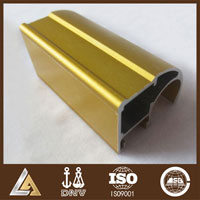

anodized champagne |

anodized bronze |

anodized black |

|

| |

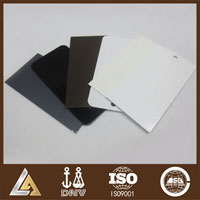

Powder coating aluminum profile

Powder coating electrostatically charges the powder and sprays it on to the aluminium extrusion, and then fuses it into a smooth painted coating in a curing oven. powder is a mixture of finely milled resin and pigment, it gives a good resistance to UV and corrosion but with various choices of colors. The chrome-based chemical pre-treatment increased better adhesion between profile surface and powders, coating thickness is normally 60 – 120 μm. |

|

|

|

|

| PVDF coating |

powder coating |

powder coating aluminum profile |

powder coating aluminum profile |

|

| |

Triacid polished aluminum profile

Triacid polishing is a kind of chemical polishing method by dipping the aluminum profiles in strong oxidizer to obtain a super bright mirror surface, glossiness over 600. Triacid means three acid liquor of phosphoric acid, sulfuric acid, nitric acid. Firstly profiles are mechanical polished then for triacid polishing to make surface has various styles of shines. 2μm oxide layer thickness on aluminum profiles for bathroom and shower room. |

|

|

|

|

| two acid polished aluminum profile |

triacid polished aluminum profile |

triacid polished aluminum profile |

triacid polished aluminum profile |

|

| |

Polished aluminum profile

Mechanical polishing is performed on aluminum profiles with automatic sisal and cotton wheel, its purpose is to remove surface defects such as naturally oxidized film and eliminate the extrusion scratching mark or extruded lines on the profile surface, so that the profile surface can be smooth and get a bright shining mirror effect on the surface of aluminum profile. |

|

|

|

|

| polished silver aluminum profile |

polished silver aluminum profile |

polished silver aluminum profile |

polished bronze aluminum profile |

|

| |

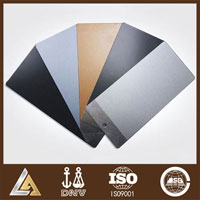

Sand blasting aluminum profile

Sand blasting is one of the profile surface pretreatments, which tends to create a matt dull surface by propelling a stream of abrasive fine steel beads at a high pressure to smooth mill finish profiles without getting damaged. And glass beads blasting is the process of removing surface contaminants to get a uniform surface finish on aluminum profiles by applying moderately abrasive glass beads. |

|

|

|

|

| sand blasting anodized silver matt |

sand blasting anodized champagne matt |

sand blasting anodized bronze matt |

sand blasting anodized black matt |

|

| |

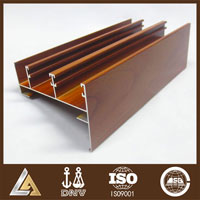

Wood grain aluminum profile

Wood grain is thermal transfer printing the wooden texture onto the aluminum profile. For getting better adhesive attraction, pretreatment of thin layers powder coating is needed. then wrap aluminum profiles by pre-printed wooden texture paper and film, curing in a vacuum wood grain machine, affecting the decoration by converting ink pigments from solid into gas and back again to solid within the painting layer, lastly remove the paper and film after cooling. |

|

|

|

|

| wood grain |

wood grain |

wood grain |

wood grain |

|

| |

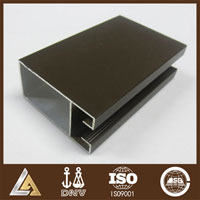

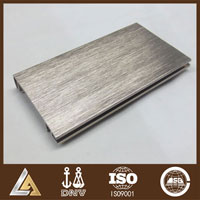

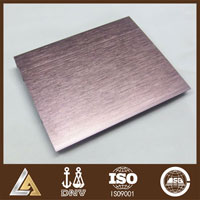

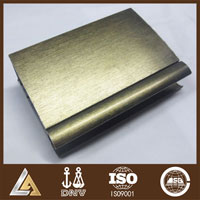

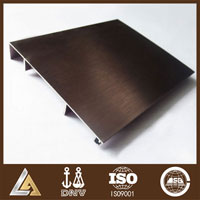

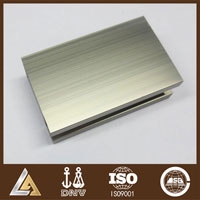

Brushed aluminum profile

Brushing creates a unidirectional satin finish and provides a silky-matt finish on profile surface, it gives aluminum a distinctive look, as it retains some but not all of its metallic lustre and is given a pattern of very fine lines parallel to the brushing direction. |

|

|

|

|

| brushed aluminum profile |

brushed purple aluminum profile |

brushed champagne aluminum profile |

brushed bronze aluminum profile |

|

| |

Electrophoretic painting aluminum profile

Electrophoretic painting is to cover acrylic resin paint evenly on the aluminium profiles and sealed without porosity, this immersion wet paint finishing process uses electrical current to attract the painting onto the aluminum surface by submerging the profiles into painting tank for the coating bath or solution, profiles can be painted both inside and out, wherever the liquid is able to reach the aluminum surface. |

|

|

|

|

| electrophoretic painting champagne aluminum profile |

|

|

|

|

| |

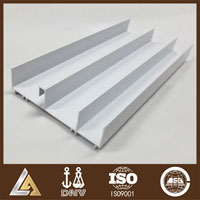

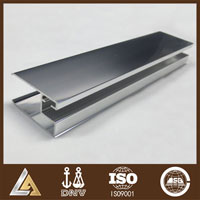

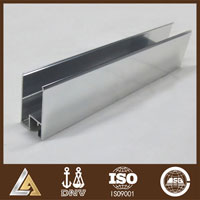

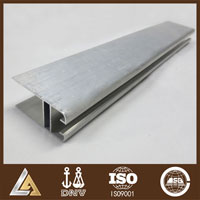

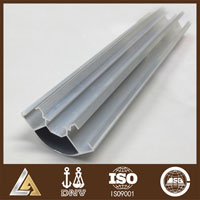

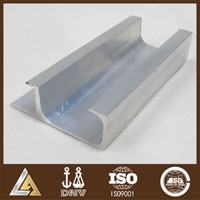

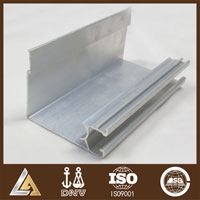

Mill finish aluminum profile

Mill finish is basically bare aluminum, it is the natural appearance of the aluminum, the extrusion profiles without any surface treatment as it comes from the extrusion die, it is simple products after the extrusion processing. The appearance is natural color of aluminum in sliver, as without any surface treatment, there will be some die lines as surface texture, but without any external mechanical or chemical finishing or colouration. |

|

|

|

|

| mill finish |

mill finish |

mill finish |

mill finish |

|

| |