|

Anodized aluminum profiles |

Home >> Aluminium profiles |

Anodized aluminum profile

Anodizing aluminum means mill finished aluminum with anodizing process, the anodizing color can be matt silver, anodized champagne, anodized bronze, anodized black, anodized gold and some other colors. Aluminum profiles are anodized by immersing them in an acidic electrolyte, a direct current runs through the acidic solution and the profile becomes positively charged, the electricity causes some of the oxygen ions in the water to get attracted to the aluminum surface and it reacts with the extruded aluminum to create aluminum hydroxide and other compounds. The anodized film can increases the thickness of the oxide coating on the aluminium improving its resistance to abrasion. The electrolyte used for anodizing conducts electricity but it also attacks the anodized film and dissolves part of it. As this formation and dissolution continues, the anodized film creates a coating with microscopic holes that extend from the surface of the coating to the base that is touching the raw extruded surface. This makes it possible for any colored coating placed on the anodized aluminum profile surface to have a beautiful appearance. |

|

|

|

|

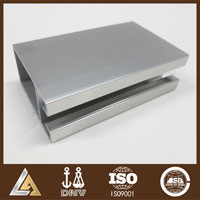

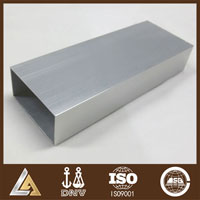

| anodized silver |

anodized champagne |

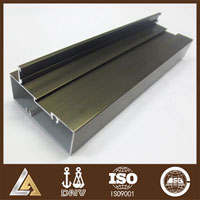

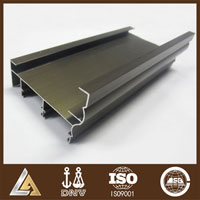

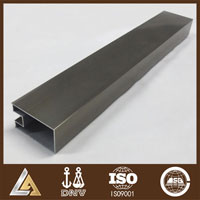

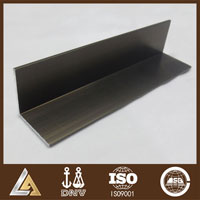

anodized bronze |

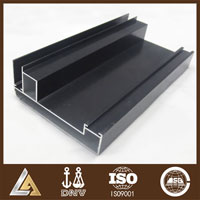

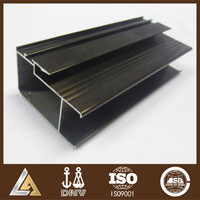

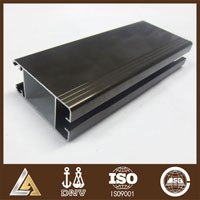

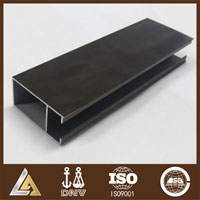

anodized black |

| |

|

|

|

|

|

|

|

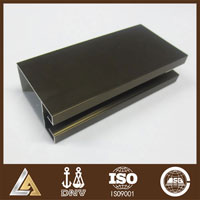

| anodized silver |

anodized bronze |

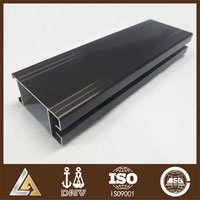

anodized bronze |

anodized bronze |

| |

|

|

|

|

|

|

|

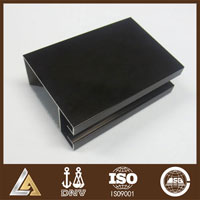

| anodized bronze |

anodized bronze |

anodized bronze |

anodized bronze |

| |

|

|

|

|

|

|

|

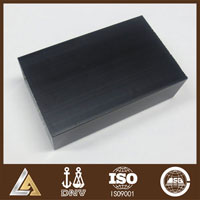

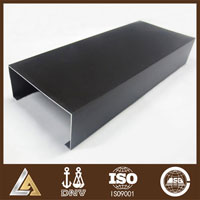

| anodized champagne |

anodized champagne |

anodized champagne |

anodized champagne |

| |

|

|

|

|

|

|

|

| anodized champagne |

anodized champagne |

anodized champagne |

|

|

Anodizing of aluminum profiles is performed through an electrochemical process. During this process, an anodic (oxide) layer is built on the metal surface. This oxide layer serves as an insulator and it may be tinted with a wide range of colors. Anodizing prevents surface corrosion and acts as a substrate for additonal decorative finishes. It also improves hardness and wear resistance. |

The most common type of aluminum anodizing is performed through bath solution, an anodizing film with thickness 6~15μm can be created when charged electricity to keep constant temperature. The anodized film has a translucent look before a dye is applied to it. The final anodized profile can be dyed to any desired color. The tiny holes in the anodized coating help to absorb the dye and the coating is sealed.

|

The anodizing processes can be alkali etching and acid etching, also some extruders make the polishing, sand blasting or shot blasting operation on the aluminum profile before anodizing to remove the die line and scratch. The anodizing aluminum surface will be smooth and elegant and it is widely used in window and door, curtain wall, industrial profiles and decoration profiles. As anodizing process can make different color, so anodizing aluminum are most popular in the market. |

| |

Advantages of Anodized Aluminum

Anodizing gives the surface of aluminum a high quality finish that delivers high performance. Here are some of the benefits of using this type of surface finsh:

Enhanced Durability: Anodized products have a much longer lifespan and this makes them more cost effective. They require less maintenance and this can lead to significant savings. Anodizing creates a perfect bond with the aluminum so it remains intact for many years.

Stable Color: The anodized film creates microscopic holes to get color tinted then sealed, so the external coating of anodized profiles provides greater stability in the presence of the sun's harsh ultraviolet rays. The coating provided by anodizing is part of the metal so it does not form flakes or blisters, neither does it chip nor peel off.

Easy to Clean: Most anodized aluminum profiles do not get stained or absorb surface dirt. So with a mild cleaning solution, the surface can be restored quickly to its initial appearance. If paint is used to write on an anodized surface, it is very easy to remove with a cotton cloth and a solvent because anodizing is resistant to virtually all paint solvents.

Visually Appealing: Anodizing delivers an ever increasing number of color and gloss alternatives. Exact matching of colors is also easier with an anodized finish and it is the best finish that retains the metallic appearance of the aluminum surface.

Safe and Healthy: Anodizing is safe and chemically stable. Since it does not decompose, it is resistant to heat and non-toxic. The process simply reinforces a natural oxidation process, and it produces no harmful by-products.

Hardness: Aluminum profile offers different hardness in T4(HW7) , T5(HW9) or T6(HW11). 6063 aluminum profile is suitable for making doors and windows in commercial buildings that are opened frequently due high traffic.

|

| |

|

We export aluminium profiles to South Africa, East Africa, West Africa, North Africa market like Algeria, Nigeria, Benin, Ghana, Senegal, Cameroon, Kenya, Tanzania, Ethiopia; And South American market like Brazil, Columbia, Ecuador, Peru, Chile, Argentina, Paraguay, Mexico; Also South-East Asia market like Philippines, Thailand, Vietnam, Burma, Nepal, Malaysia, Indonesia; And Middle East countries like Turkey, UAE, Israel, Iran; And European countries like Russia, Ukraine, Netherland, Poland, Italy, Spain and Australia etc. |